Conditioning Equipment

-

Structural Steel Frames

-

Rectangular Holding Bin Systems

-

Access Manhole Doors

-

Chemical Containment Systems

-

Rebag Systems

-

Overhead Bulk Scales

-

Systems Dust Filter Units

-

Custom Hoppers, Transitions and Valves

-

Retrofit Spiral Separator Doors

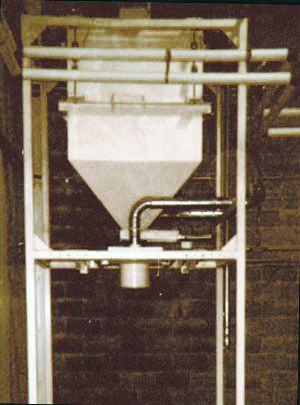

Structural Steel Frames

- Custom frames for processing buildings and bin supports

- Turnkey design and fabrication services available

- Structural designs to meet UBC or other local codes

- Bolted or welded connections depending on application

- Sandblasted and phosphatized metal preparation

- White, gray, or red primer, optional enamel paint

Custom structural frames are used to support holding bins, conveyors, and conditioning equipment. Our staff has design and fabrication experience with seed conditioning towers, sheller buildings, and large elevated conveyor structures, as well as many smaller equipment stands and access platform supports.

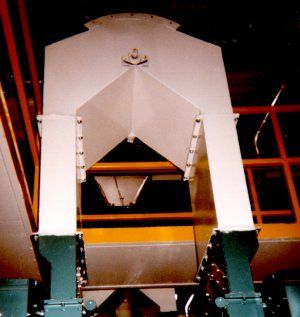

Overhead Bulk Scales

- Net weigh design for rapid weighing during bag placement

- Automatic feed system cutoff at desired bag weight

- Adjustable bag holders and concentric inlet spout

- Adaptable to fill either bulk bags or pallet boxes

- Dust ports for external dust system piping

- Options for PLC interface, pallet conveyor

These units are designed to meet increasing demand for large volumes of bulk seed products. Seed is weighed in the overhead bin during bag placement, increasing bag throughput compared to traditional methods. The bag is held in position by a circular inlet spout and adjustable cantilevered loop holders. Concentric inlet spouts are used to remove excess air from the bag during the filling operation. Product can be supplied from an overhead bin, spout, or variable speed belt conveyor.

Bin Outlet Gates

- Design and fabrication of custom hoppers and fittings

- Configurations for most inlet and outlet requirements

- Custom directional valves, spouts, and ductwork

Most seed facilities require a wide variety of custom hoppers and fittings to connect equipment from different vendors or for installation in confined areas. AEC personnel have extensive experience with custom fittings, and can custom design and build to suit your requirements.

Rebag Systems

- Systems for emptying bags and boxes

- Free standing or integrated applications

- Platforms for depalletizing or bag access

- Knife boxes for cutting of seed bags

- Dust collection hoods and grates

- Multiple discharge designs

Rebag systems include equipment for unloading seed from conventional bags, large bulk bags, or pallet boxes. Unloading hoppers, access platforms, and knife boxes are available to meet specific local requirements.

Dust Filter Units

- Passive cloth filters and cyclone dust collectors

- Cyclones available in multiple diameters

- Modular filter units adapt to a range of airflow volumes

- Filter bags in 9”, 12”, and 24” diameters

- Zipper bottom or open end bags for outlet hoppers

- Optional outlet transitions, airlocks, and bin activators

Dust collectors are used to remove nuisance dust from exhaust air. Cyclone type collectors are simple, low cost units which separate heavy dust particles by centrifugal force. Passive bag filters use oversize cloth bags to filter dusty air, and operate at higher efficiencies than centrifugal separators. Both types are sometimes used in series when handling extremely dusty air or large particulate material such as cobs.

Retrofit Spiral Separator Doors

- Hinged steel access doors for spiral cabinets

- Adaptable to new or existing separators

- Toggle latches and door seals for dust control

- Sturdy glass window for product visibility

- Bolted frame for easier field installation

Retrofit doors replace the existing plastic panels found on many existing spiral separator cabinets. These doors provide a larger access opening and better dust control than older designs, and can be equipped with removable “lift off” hinges when required. The oversize window kit permits visual inspection, limiting the need to open the door during operation.