Seed Storage Equipment

-

Pallet Boxes

-

Magnetic Separators

-

Rectangular Spouting

-

Letdown Ladders

-

Bin Outlet Gates

-

Cob Bins

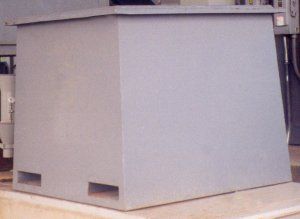

Pallet Boxes

- Fabricated boxes for bulk seed storage

- Easily moved with a standard forklift

- Formed steel upper flange and tag holder

- Multiple sizes and materials

- Optional covers, aeration, and lift hooks

These fabricated steel boxes are designed for storage of small lot bulk seed products. Boxes can be stacked using optional steel covers, and have formed upper flanges to eliminate sharp edges common to many other box designs. Solid floors are standard equipment, however, partial perforated floors for aeration can be provided as an option. Boxes can be unloaded using a box dumper or commercial tilt head forklift. Hopper bottom pallet boxes can also be provided on a custom basis.

Rectangular Spouting

- High capacity and/or low headroom spout applications

- Available in many sizes, flange patterns, and steel gauges

- Optional wear liners, access lids, and sight windows

- Custom transitions and valves bid on request

Rectangular spouting is generally used to eliminate extra transitions between rectangular valves and equipment inlets. This frequently reduces the height required to obtain a given flow rate. Standard sizes range from 6″ to 12″ square, however, other sizes can be easily fabricated on a custom basis. Rectangular transitions are also available, including elbows, square to round fittings, cushion boxes, and flange adapters.

Bin Outlet Gates

- Manual, rack & pinion, or air operated designs

- Low profile sliding design minimizes headroom requirements

- Standard sizes from 6” to 12”, custom sizes bid on request

- Optional chain wheels, air valves, and position switches

Outlet gates are used to shut off product flow from holding bins or charge hoppers using a sliding plate. Standard gates have steel wear surfaces for low headroom installations. Rack & pinion gates are extended to remove the rack from the product area, reducing potential for seed leakage.

Magnetic Separators

- Installs in a standard round spout

- Removes most ferrous contaminants

- Design reduces seed depth on magnet

- Hinged plate magnet with latch

- Damper limits bounce over magnet

- Angle ring or sleeve type fittings

- Sizes for 4”, 6”, and 8” round spouting

- Optional stainless steel construction

These units help solve problems during field installation of commercial magnets in existing round spouting. Prefabricated units are available for 4″, 6″, and 8″ diameter spouting, with other sizes and rectangular flanges bid on request.

Letdown Ladders

- Staggered curved cups reduce damage during long drops

- Open and enclosed styles, with multiple bolted section lengths

- Sizes from 600 to 5000 bph, larger sizes bid on request

- Standard liner is 1/8” gum rubber, custom liners also available

- Alternate replaceable wear liner for inclined applications

- Optional inlet adapters and hoppers, outlet transitions

Letdown ladders reduce seed damage due to long vertical drops, either inside holding bins or in transfer spouting. Open ladders permit product to flow from the lowest exposed cup as the bin fills. Enclosed ladders are designed to replace vertical spout sections. A modified version is also available for inclined locations, and features a replaceable wear liner on the lower surface. Ladder cups are generally lined with 1/8″ gum rubber, but can be supplied unlined for low volume or treated seed applications. Optional prefabricated inlet and outlet fittings are available for many applications.

Cob Bins

- Rapid unloading of cobs and similar bulky products

- Modular slide or clam gate designs

- Pre-assembled pumps with remote electric controls

- Unique baffle minimizes shear pressure required

- Sealed bearing cam wheels for slide gate support

- Bronze bushings at all clam gate pivot points

- Heavy duty mild steel construction

Cob bins provide temporary storage of non-free flowing products such as corn cobs, and utilize oversize gates to minimize bridging during product discharge. Clam gate designs are more common, however, modular slide gate designs are also available for larger installations. Hydraulic pump units are generally located away from the door, with either manual or electrically operated control valves.