AEC 3000 – Series Pallet Box Dryer

Research Seed Drying – With industry leading UL fire control panels and controls, AEC pallet box dryers provide safe, efficient, consistent and reliable operation year after year. Precise temperature control allows our system to be used on virtually any product. Our dryers are user friendly, easy to maintain and built to last in various conditions.

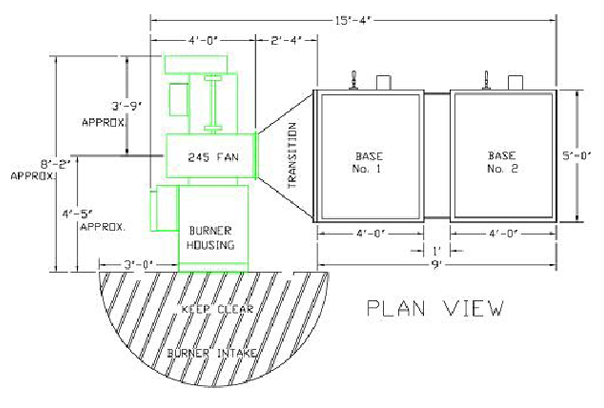

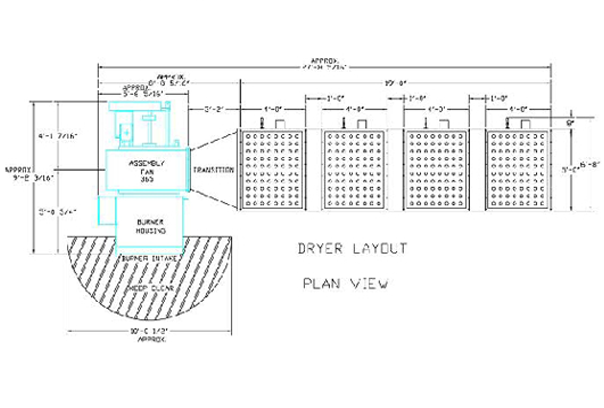

AEC pallet box dryers are available in several sizes and configurations. Plenum bases are passive in design with adjustable air baffles for precise airflow control and balance. Pallet boxes are filled with product and stacked up to three boxes high on each base.

CUSTOM TRAY DRYERS – AEC custom tray dryers have a compact footprint and are optimal for research and foundation seed facilities with space limitations. They are designed with research seed in mind and utilize electrical controls and gas trains to precisely control temperature and air flow to produce repeatable and efficient results. Research tray dryers are easy to operate with push button temperature control. AEC research dryers come with a preprogrammed microprocessor and have been thoroughly tested by the Applied Electronics Corporation team. The controls manufactured by AEC are UL listed.

Specifications

- 2, 4, 6, 8, and 10-port configurations

- Bolt together plenum bases

- Adjustable baffles for air flow regulation

- 4′ x 5′ x 3′ pallet box dimension

- External pre-assembled modular fan burners complete with fire control panel and gas train

- Class II fan

- UL listed NEMA 12 enclosure and burner control interlock and fan motor interlock

- Primary and secondary adjustable high limit thermostats

- Two stage electrically operated safety shut-off valve

- Air flow and flame detection switches with alarm

- High and low gas pressure limit switches with alarm

- Flame failure lockout through flame detector relay

- Actuator and modulating valve with precise, efficient and accurate burner control with low fire limit switch

- Inlet and intermediate lever operated ball valves

- Inlet gas pressure regulator

- Direct spark ignited split burner

- Inlet wye strainer

- Built to match United States and/or international electrical requirements

Optional Equipment and Upgrades

- “T” and “Y” configuration of dryer bases

- Magnehelic air pressure gauges in dryer bases for precise dryer balance

- Three gauge gas train upgrade (inlet, outlet, intermediate gauges mounted in gas train cover)

- Automatic staged burner control

- Automatic pilot burner ignition

- Industrial risk insurers compliance

- NEMA 4 enclosure

- 50 Hz motor available

- Rain lids

- Custom paint colors